Rewind® PET Chemical Recycling Process

Reuse systems

Addressing the challenge of recycling colored or contaminated PET waste into high-purity BHET for sustainable production.

Contact

JEPLAN, INC.

Company Established Year

Who is this solution for

Info

Available

Project Status

Looking to expand internationally

Doing business in

Awards and certifications

Good Design Gold Award

Honored BRING™ project for promoting textile recycling and sustainable apparel design in Japan.

Red Dot Award

Recognized BRING™ regenerative T-shirt and its reusable circular box for outstanding eco-friendly design and innovation.

Rewind® Commercial Licensing

Acknowledged as a breakthrough for scaling chemical PET recycling globally, after successful demonstration in Japan.

Product description

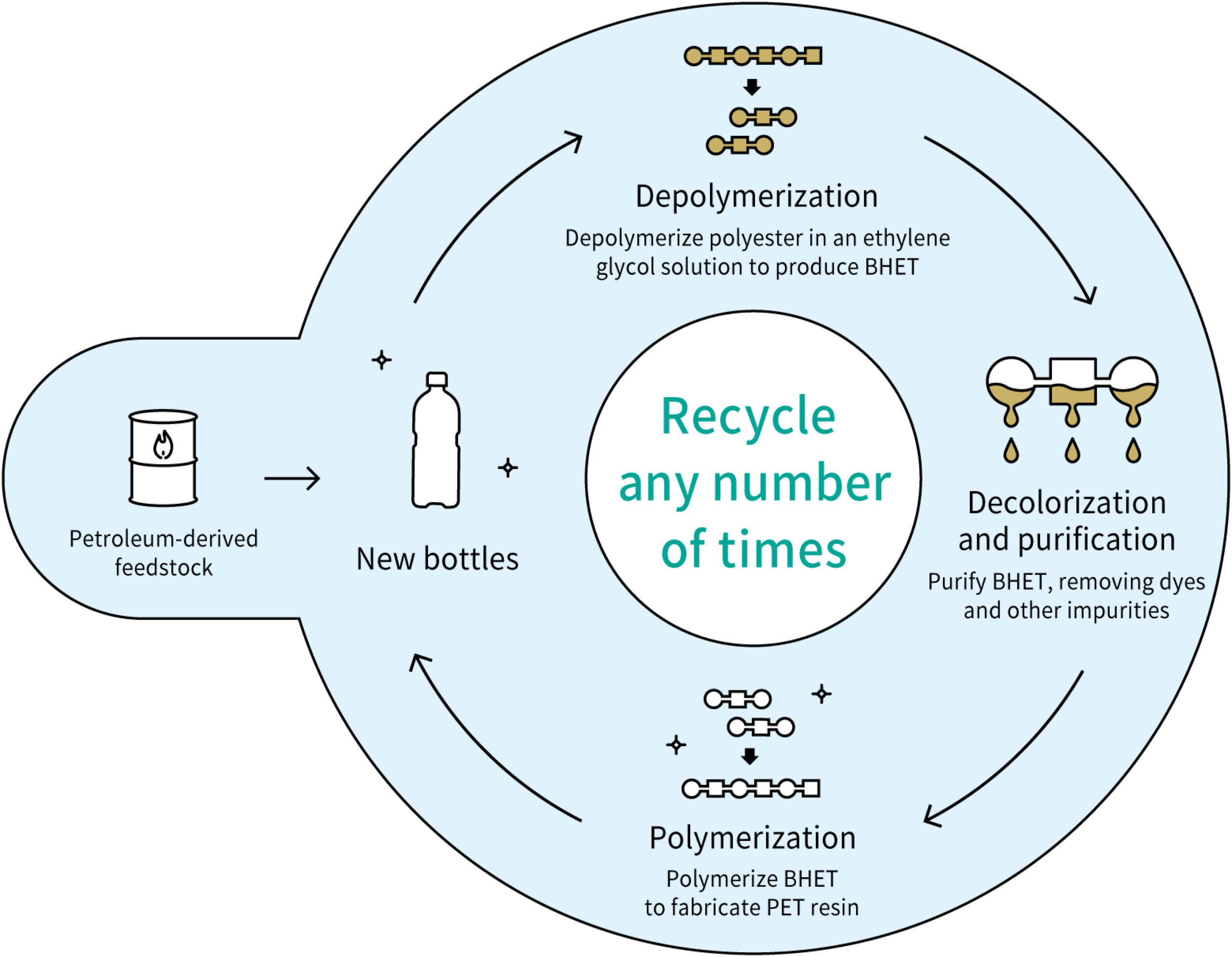

The Rewind® PET Chemical Recycling Process is a groundbreaking solution that tackles the pressing issue of recycling various PET wastes, including colored or contaminated bottles and polyester textiles, into high-purity BHET monomer. This innovative process operates continuously and employs sophisticated purification techniques such as crystallization and distillation to remove dyes, additives, and foreign substances, ensuring the resulting BHET is of exceptional quality and suitable for use in food-contact materials.

Axens, the company behind Rewind®, launched a semi-industrial demonstration plant in Kitakyushu in 2023. Following a successful year-long trial, global licensing for the process began in October 2024. This development allows manufacturers worldwide to integrate Rewind® into their production lines, thereby fostering a genuine circular economy for PET materials. By supporting 'infinite recycling' with minimal environmental impact, Rewind® enables multiple reuse cycles without compromising material quality, making it a sustainable and eco-friendly solution for the industry.

Key characteristics and environmental benefits

- Continuous depolymerization of PET waste into high-purity BHET monomer

- Sophisticated purification steps like crystallization and distillation

- Removal of dyes, additives, and foreign substances for food-contact material suitability

- Semi-industrial demonstration plant in Kitakyushu and global licensing by Axens

- Integration into production lines to promote a circular economy for PET

- Support for 'infinite recycling' with minimal environmental impact

- Enables multiple reuse cycles without degrading material quality

About the Company

Ask about Rewind® PET Chemical Recycling Process

Hi there! I’m here to help you quickly understand what this green solution is about — without needing to read the full page.

You can ask me things like:

- What problem does it solve?

- How does it help the environment?

- What makes it different?

Let’s explore together!

You can try asking:

Oops, it seems like you're not a member.

Sign up! It's free. You'll be able to read all the articles you like, download PDFs, and get in contact with the respective owners.

Have an account already? Sign in here